Reconditioning is a practice that is generally applied to used devices to make them safe and functional again. This process includes cleaning, disinfection, sterilisation, testing and restoring the technical and operational safety of each device.

According to the EU Medical Device Regulation 2017/745, the reprocessing and further use of single-use devices are only allowed in a Member State if provided for by national legislation.

So how does this practice work in Italy? What does the national legal system provide for the reprocessing of single use medical devices? Continue reading the in-depth Quality Matters dedicated to this issue!

According to the EU Medical Device Regulation 2017/745, the reprocessing and further use of single-use devices are only allowed in a Member State if provided for by national legislation.

So how does this practice work in Italy? What does the national legal system provide for the reprocessing of single use medical devices? Continue reading the in-depth Quality Matters dedicated to this issue!

Summary

The sterilisation of single-use prosthetic components

Single-use prosthetic components marketed by BioService and shipped to dental practices are non-sterile medical devices. As such, as prescribed on page 10 of the BioService Component Manual, they must "be sterilised before use following the indications given in the reference standards UNI EN 13060:2019 and UNI EN ISO 17664-1:2021.

It is suggested to sterilise with saturated steam autoclave under pressure at 134°C - 2 atm for 10 minutes (time calculated from the moment the indicated temperature and pressure values are reached).po calcolato dal momento in cui sono stati raggiunti i valori di temperatura e pressione indicati).

After sterilisation, the product must remain in the pouches used for sterilisation. The pouches should only be opened immediately before use. The shelf life of sterilised products inside the pouches must not exceed the period recommended by the pouch manufacturer.

Laboratory analogues, castable components and overfusion abutments must not be sterilised."

It is suggested to sterilise with saturated steam autoclave under pressure at 134°C - 2 atm for 10 minutes (time calculated from the moment the indicated temperature and pressure values are reached).po calcolato dal momento in cui sono stati raggiunti i valori di temperatura e pressione indicati).

After sterilisation, the product must remain in the pouches used for sterilisation. The pouches should only be opened immediately before use. The shelf life of sterilised products inside the pouches must not exceed the period recommended by the pouch manufacturer.

Laboratory analogues, castable components and overfusion abutments must not be sterilised."

What is meant by 'single-use'?

Single-use means that each individual device is to be used exclusively for a single patient.

It is customary for a prosthetic component to be tried on in the mouth even several times and to be sent back to the dental technician for prosthetic finalisation. This practice is permissible and does not alter the concept of single use as long as the same prosthetic component is only ever used for the same patient.

In cases of multiple prostheses, on the other hand, it is important that the same component is only ever used in the same position and in connection with the same implant, i.e. that components are not interchanged within the same rehabilitation.

As specified in the aforementioned Component Manual, "Any reuse in different patients must be considered an off-label use and, in such cases, BioService S.r.l. disclaims any liability. Reuse of products indicated as disposable, in fact, if not strictly controlled and in compliance with the relevant regulations, may result in product contamination, patient infection and/or implant failure'.

It is customary for a prosthetic component to be tried on in the mouth even several times and to be sent back to the dental technician for prosthetic finalisation. This practice is permissible and does not alter the concept of single use as long as the same prosthetic component is only ever used for the same patient.

In cases of multiple prostheses, on the other hand, it is important that the same component is only ever used in the same position and in connection with the same implant, i.e. that components are not interchanged within the same rehabilitation.

As specified in the aforementioned Component Manual, "Any reuse in different patients must be considered an off-label use and, in such cases, BioService S.r.l. disclaims any liability. Reuse of products indicated as disposable, in fact, if not strictly controlled and in compliance with the relevant regulations, may result in product contamination, patient infection and/or implant failure'.

Reprocessing single-use medical devices: EU Regulation 2017/745 and Italian legislation

The European Regulation (EU) 2017/745 on Medical Devices now known as MDR, takes up the concept of reprocessing single-use devices already enshrined in Directive 93/42/EEC, placing new limits and serious burdens on healthcare institutions.

It should be immediately underlined that, to date, the Italian State has not yet expressed its consent to authorise such a procedure by means of a regulatory act; therefore, the reprocessing of single-use medical devices remains unauthorised until express Italian acceptance.

In any case, should the authorisation be granted, natural or legal persons reprocessing single-use devices will have to comply with Article 17 of the MDR, which places the full responsibility for the product on the reprocessor: the latter is considered as the manufacturer of the reprocessed product and assumes the same obligations imposed by the Regulation on all manufacturers of medical devices, including the costly traceability obligations.

A derogation from what has just been said comes in handy for healthcare professionals, but in any case leaves ample room for burdens and controls on the devices, all in order not to fail to meet the cornerstone of the entire medical device regulation, i.e. the high standard of product performance and quality.

It should be immediately underlined that, to date, the Italian State has not yet expressed its consent to authorise such a procedure by means of a regulatory act; therefore, the reprocessing of single-use medical devices remains unauthorised until express Italian acceptance.

In any case, should the authorisation be granted, natural or legal persons reprocessing single-use devices will have to comply with Article 17 of the MDR, which places the full responsibility for the product on the reprocessor: the latter is considered as the manufacturer of the reprocessed product and assumes the same obligations imposed by the Regulation on all manufacturers of medical devices, including the costly traceability obligations.

A derogation from what has just been said comes in handy for healthcare professionals, but in any case leaves ample room for burdens and controls on the devices, all in order not to fail to meet the cornerstone of the entire medical device regulation, i.e. the high standard of product performance and quality.

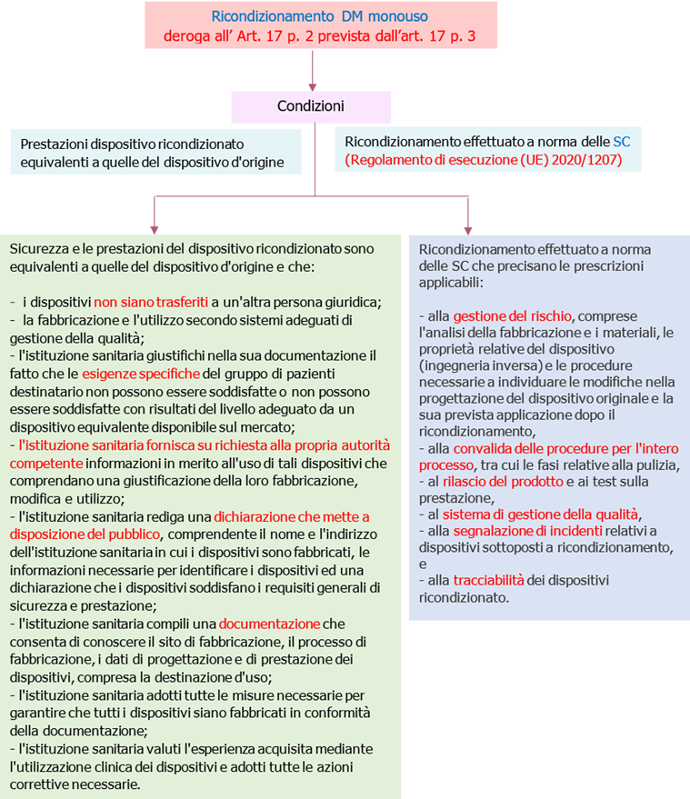

Paragraph 3 of Article 17 specifies that Member States may decide not to apply all the rules on manufacturers' obligations set out in the regulation as long as they ensure that:

(a) the safety and performance of the reprocessed device is equivalent to that of the original device and that the requirements of Article 5(5)(a), (b), (d), (e), (f), (g) and (h) are fulfilled;

b) the reprocessing is carried out in accordance with the Common Specifications contained in the Enforcement Regulation (EU) 2020/1207.

In order not to go into too much legal detail, we propose the following diagram that briefly summarises the obligations contained in (a) and (b).

Bibliography

Regulation (EU) No 2017/745 of the European Parliament and of the Council of 5 April 2017 on medical devices